GLOBAL – The panel processing and furniture industries first contact with the “Zero Joint” or “Laser Edge” technologies can be traced back to Ligna 2009.

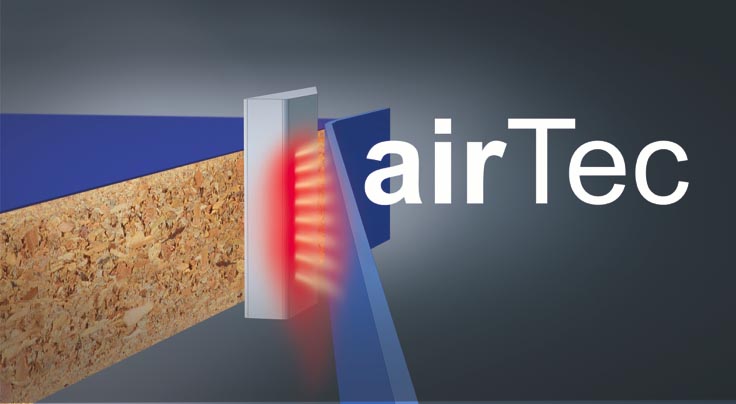

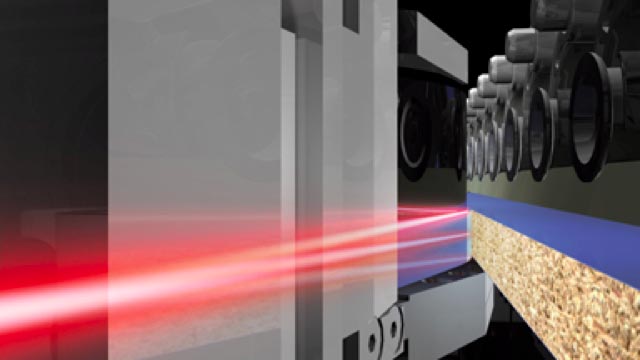

It was during this tradeshow that the Homag Group, the global leader in panel processing machinery, first introduced its laserTec technology. By 2012 as reported by renown german wood industry portal EUWID this technology, that eliminates the use of adhesives and considerably upgrades the quality of the finished part by eliminating the visible line when joining the part with the edge strip, an estimated 150 machines had been sold mainly in Germany, Austria and Switzerland by german manufacturers Homag and IMA.

Among those early adopters were many of the larger office and kitchen furniture manufacturers including manufacturers in North America. In the Ligna 2013 the leading machinery manufacturers introduced and emphasized a new technology that delivered the same quality as the laser technology (zero joint) based on hot air and with an important investment cost differential for furniture manufacturers.

The hot air alternative has considerably increased interest in zero joint edgebanding among smaller manufacturers in the last two years and many have started to invest in machinery with this technology.

In Australia where the furniture industry is composed mainly of small and medium sized manufacturers, the rate of adoption of hot air edgebanding technology among manufacturers is specially noticeable as reported in the latest issue of AWISA magazine. Early adopters of this technology specially appreciate the undoubtable quality differentiation of the finished product that zero joint edgebanding delivers to the customer giving them the advantage of being pioneers in their respective markets.

0 Comments