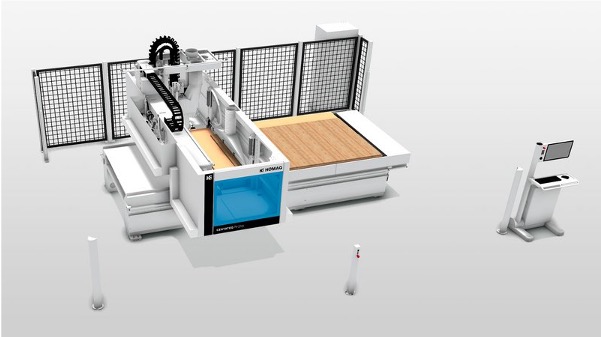

GERMANY – Homag launches a new generation of machines for nesting applications CENTATEQ N-210 and CENTATEQ N-510, where sustainability, flexibility and performance are highlights.

In addition to the table structure, the vacuum, air cushion concept, and material handling components have been rethought and further optimized. To optimize non-productive times and setup, the tool changing system has also been adapted.

After starting with the basic version, the machine can be upgraded to meet the current needs of the customer.

High volume processing is also a focus within the new CNC Machining Centers CENTATEQ N-210 and CENTATEQ N-510 programs. Homag offers a lifting table on the left-hand side and a belt conveyor on the right-hand side. The lifting table always moves to the desired height and the feeding of the panel onto the processing table is enabled automatically. Depending on the depth of the machine, this infeed device can consist of an increasing number of suction cups, which can be extended if when the panels to be processed carry a higher weight. A new feature is the integration of the infeed device into the machine housing. In addition to the advantages of protecting the components from dust and debris, this is also an absolute added value in terms of long-term reliability.

The Homag Group is the world’s leading provider of integrated solutions for production in the woodworking industry and woodworking shops.

0 Comments