ITALY – Stefani’s edging solution “J- Shape” won the first prize at the XIA – XYLEXPO Innovation Awards in the Panel Machining category. The jury praised its “excellent ability to provide answers to market needs for edgebanding of ergonomic profiles in reduced operation spaces, using polyurethane adhesives with small radii of curvature and thick edges.”

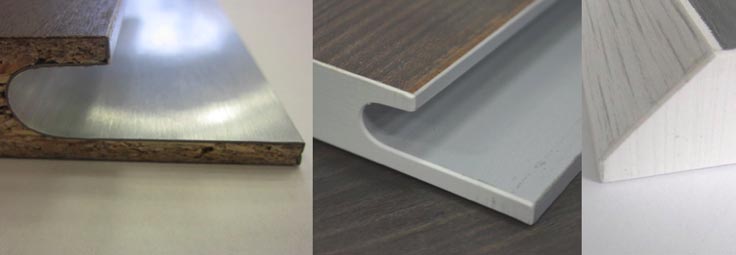

J-Shape is the highest expression of the technological evolution in the machining of softforming edges. With this technology developed by Stefani of the SCM Group furniture can now be designed and manufactured industrially with more attractive and minimalist features.

For example, it is possible to remove the handle, integrating it in the profile of the panel itself whilst maintaining the continuity of finishings and decorations.

It is also possible to produce tops, tabletops, cabinet doors and drawers, all with inclined edge profiles up to 60° for new sensations of lightness. And the possibility of applying edges even up to 2 mm thick results in long lasting aesthetics of the machined parts, with improved resistance to daily wear and tear.

Federico De Santi, Area Manager for Latin America in SCM explained the scope of this innovation, “It is important to note that this evolution of J-Shape works with our exclusive Slim Line technology, the process by which the polyurethane glue adheres to the edgeband and then is fixed to the panel, thus bringing important advantages: Less adhesive required (the panel does not absorb the adhesive) achieving a better finish and therefore with lower costs.”

The award-winning J-Shape has been well received by the industry. Major manufacturers have decided to invest in this differentiated technology, including leaders such as Alvic Group and Porcelanosa Group from Spain, Browns 2000 from the UK, Egepres from Turkey and Sunhe, Victory and Tona Bathroom from China, among others.

0 Comments