ITALY – Whether large-scale batch-size-1 production or sophisticated (small) batch production – the IMA Schelling Group promises to provide the optimal solution to any need.

Moreover, Schelling will present its fh 5 panel saw. This accurate and versatile panel saw provides flexible cutting capabilities for single panels and groups, which makes it suitable both for use in sophisticated small businesses and industrial corporations.

Also on display will be Schelling’s newly developed scissor lift device. The patented scissor lift device allows for optimal storage area utilization with widths of 4 to 20 m and lengths of 120 m; greater lengths can be realized on request. Due to its intelligent design, the scissor lift device can be designed with a lift stroke of up to 4700 mm, which enables the area storage system to be operated at a floor level located above that of the panel saw.

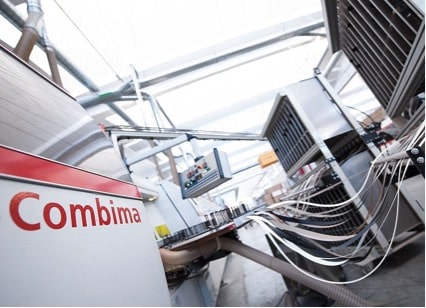

In the course of the Xylexpo, the IMA Schelling Group will present itself for the first time with its partner, SIRIO. Together they brought many projects into being, amongst other things the batch-size-1 project. The panel cutting facility and the Combima edgebander were supplemented with functionalities provided by SIRIO. The Italian company is responsible for logistics & handling and the supervisory control system.

0 Comments