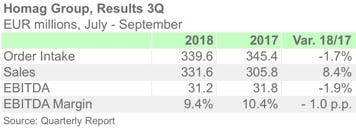

GERMANY – Homag Group had a very good 3Q-2018 as sales grew 8.4% to € 331.6 million compared to € 305.8 in the 3Q-2017. But in the first nine months of the year sales have fallen short of expectations, rising by only 3.7% to € 937.3 million (9M-2017: € 903.8 million).

Against this backdrop, the EBITDA margin contracted from 10.4% to 9.4% in the first nine months of 2018 and order intake reached € 1,041 million, falling by 3.5 percent compared to the high level of the previous year (9M-2017: € 1,079 million).

In addition to the reorganization of production processes at Schopfloch – which will allow it to handle orders for complete systems more quickly and efficiently – Homag is intensifying cost controls. With these measures the company is addressing the challenges of 2018 and expects to see swifter growth in sales and earnings in the fourth quarter.

In the 3Q-2018 breakdown by region, business continued to develop positively in North and South America. “In the USA, we even recorded double-digit growth,” emphasizes Homag CEO Pekka Paasivaara. “Systems business with industrial clients was similarly good in Europe, where we achieved double-digit growth in Germany. In China, on the other hand, the systems business temporarily calmed down after the strong years 2016 and 2017. We expect the China market to come back again in 2019. Overall, it is evident that many customers see us as their strategic partner of choice in the systems business. We expect ongoing growth in this area in the future. However, our focus will also remain on customers in the woodworking shop segment, who are increasingly demanding connected and automated cells from our portfolio.”

0 Comments