GERMANY – The Swiss wood-based panel manufacturer Swiss Krono commissioned Dieffenbacher to supply a state-of-the-art particle board plant.

Planned as a replacement investment, the plant has an annual capacity of around 400,000 m³ and was designed to manufacture conventional particle boards in thicknesses ranging from 6 to 60 mm, as well as thin boards up to 2.5 mm thick and lower-density lightweight particle boards. The scope of supply includes the gluing system, forming station, forming line, press and diagonal saw. Along with the new CPS+ press, the plant features additional innovative machine components that could set new standards around the world. “This project includes the most state-of-the-art equipment currently available on the market. We are proud that we were able to win over Swiss Krono with our innovative machine concept”, says Bernd Bielfeldt, head of the Wood Business Unit at Dieffenbacher.

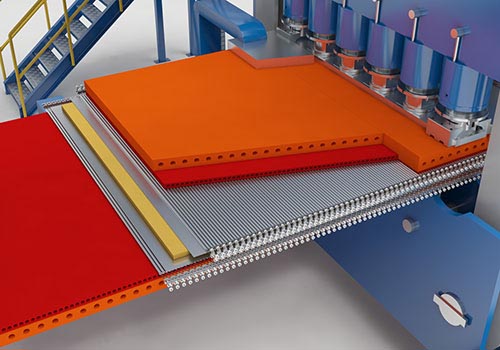

For the gluing system, the plant uses the Dieffenbacher EVOjet P, introduced in 2013 and well established in the market. The EVOjet P achieves glue savings of up to 15% compared to conventional particle board gluing systems. The plant is also equipped with a Formator P — the most innovative forming technology available. At the heart of the plant is the new CPS+ continuous press with a length of 34.5 m and a width of 2400 mm. The infeed offers highly flexible adjustment options and the press comes with optimized pressure distribution — these are the crucial features that enable superior board tolerances to be achieved. When it comes to automation, Dieffenbacher uses state-of-the-art German technology from Siemens.

0 Comments