ITALY – At the new IDEA tradefair, held from 12 to 15 April 2016 in Bergamo, Titus presented the Titusonic ultrasonic fastening solution for hollow core boards.

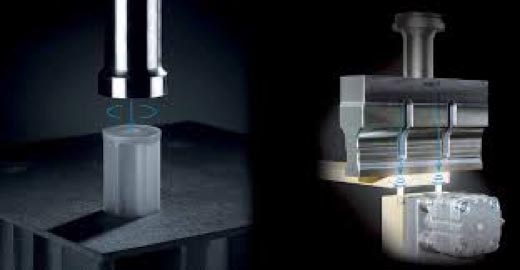

IDEA tradefair focuses on innovative products and new technologies for the furniture industry and ran paralel to iSalone in neighboring Milano. It was the opportunity chosen by Titus to present the Titusonic Gateway 1000 ultrasonic welder. With rising demand for hollow core board (HCB) in furniture, the Titusonic process presents a cost effective solution to attach fittings to frameless honeycomb boards. This solution bonds Titusonic plastic inserts into HCB and enables strong fixing into both surface laminates. The process is fast, under one second of bonding time, and clean, no glue is required.

Titusonic is a fastening solution with many years in the market that uses ultrasound to bond wooden materials replacing the commonly used wooden dowel and glue in the construction of cabinets and other furniture products. Based on the patented WoodWelding® fastening process Titusonic is highly productive. Fast process times enables a high level of production output and it is glue free, hence no clean down or setting up of glue application machinery. This solution – up to 30% stronger than a traditional glued wooden dowel – can be used to attach most types of fittings to wood based substrates, including particleboard, MDF, and now also frameless honeycomb boards.

0 Comments