GERMANY – Rehau, one of the leading manufacturers of edgebands with more than 20,000 different edgeband designs, three product groups and an extensive range of surface finishes, introduces #edge is digital, an innovative service towards a Smart Factory future.

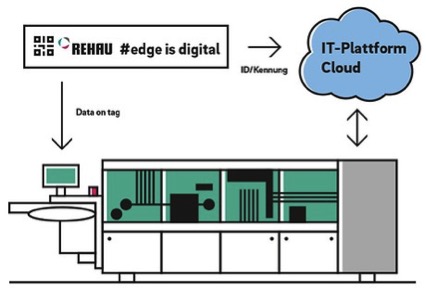

Edgebands are linked with the customer’s machine using “data on tag” (Barcode/2D code/QR code) on the edgeband coil or via a Cloud-based connection, providing actual and/or instance data, such as width, thickness, material, version, color or even the coil length, in digital form. This service makes things easier for several departments, e.g. warehouse management, incoming goods and material planning. In terms of production, #edge is digital simplifies device operation, saves time, and minimizes errors and risks. “This marks major progress in terms of process control and quality management, pointing the way for Industry 4.0 in the field of industrial furniture production,” comments Matthias Hacker, Project Manager and Senior Engineer for Rehau’s Edgeband Division.

0 Comments