GERMANY – The worldwide first industrial digital printer for the printing of wood, stone and creative décors on décor paper is being put into operation. The production location is Arnsberg – headquarters of the international décor printer Interprint.

“Digital printing is an important part of our corporate strategy. We have worked many years towards this breakthrough and have gained comprehensive know-how. The entire Interprint team is very delighted that we have jointly achieved it,” said Frank Schumacher, spokesman of the Interprint Management Board, and added: “With this printer, we can offer our market partners a real additional benefit – not only more flexible batch sizes but also a wide range of digitally printed décors.”

Interprint sees the new printer as an important supplementation of the classic intaglio printing. Newly developed décors can also be economically produced in smaller quantities with this technology. It will also be used to print individual décors in small quantities.

Holger Dzeia, Marketing & Sales Director at Interprint, explained the background of this investment: “Our customers want more flexibility, especially in the batch size of new décors for first smaller production batches or market tests. This subsequently allows, in the case of increasing quantities, a “seamless” transition to a production with décor intaglio printing. Our customers now also have the possibility of procuring smaller quantities at low prices at the end of a décor life cycle. Interprint can thus offer problem solutions that have previously not been possible in our industry. We are already looking forward to the exciting dialogue with our customers. We are now able to more individually satisfy their wishes and enquiries”.

The innovative single-pass inkjet printer, designed and built in co-operation with a large international printer manufacturer, has a maximum printing width of 1,680 mm and a printing speed of up to 150 metres/minute. A data transfer speed of 2.2 terabytes/second ensures the continuous data flow.

Exclusive Interprint system solutions ensure that conventional décor paper can be printed with water-based inks with the usual high light-fastness. That guarantees a problem-free impregnation and further processing.

“Interprint positions itself again as technology leader in décor printing with this digital printer,” said Robert Bierfreund, Engineering Director at Interprint. “This printer is a real worldwide innovation. After many years of preparatory work and with great enthusiasm in research & development, we now have a technology with a performance range that makes it possible to efficiently mass-produce digitally printed décor papers. Our team can be really proud of that.”

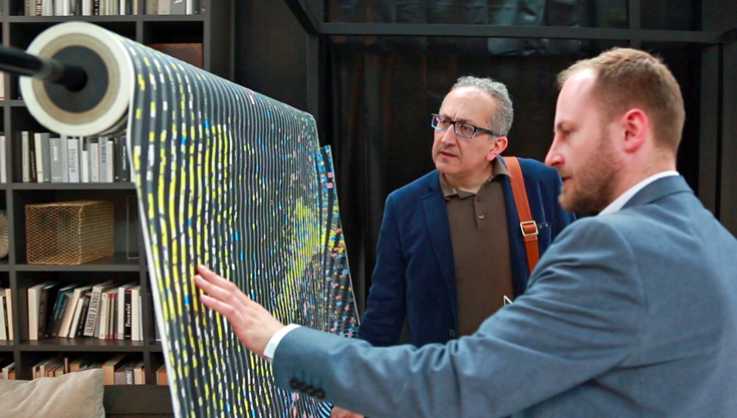

At the beginning of May Interprint presented the new technology for the first time to the international trade visitors at the Design Post Cologne.

0 Comments