DENMARK – Tvilum invested in a fully automatic foil wrapping system that dramatically increases their capabilities and meets the increasing demand for U and L-shaped edge profiles and finishes.

Tvilum’s Technical Manager, Sven Harry Nielsen, was responsible for purchasing and implementing the foil wrapping system. He notes a number of major advantages of using this technology in furniture production. “This type of technology and material processing offers a number of unique advantages which are hard to achieve using other methods. When edges are wrapped, the joins become virtually invisible, as the glue is concealed. We can also guarantee the same color and structure on the surface and edge, because the foil is wrapped in a single piece, with no overlaps,” he says. “It is also a unique production platform that enables us to supply items with U and L-shaped edges, with angles down to 45 degrees”, he added.

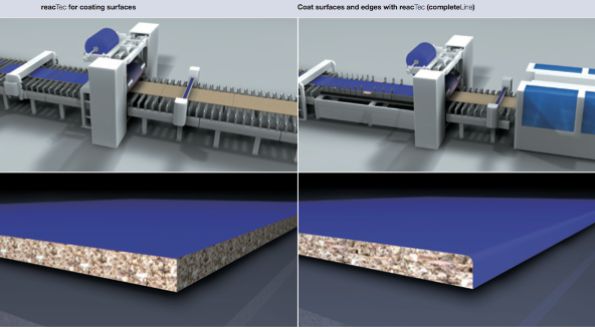

Homag’s reacTec foil wrapping system can handle chipboard 12-40 mm thick, in lengths of up to 2.5 meters and lengths of up to 1.2 meters. The machine can handle high volume, processing an average of 40 meters of chipboard per minute. This corresponds to 50,000 items per day and the machine can apply 40-80 grams of foil per square meter.

Very importantly, Tvilum’s machine operators can retool production in less than an hour, to change widths, thicknesses and edge profiles. It also takes less than an hour to switch to a different item.

0 Comments