SWEDEN – Another European manufacturer signs agreement with Välinge for use of its award winning Threespine® click furniture assembly technology. This time the turn was for TNC-Components, one of the largest furniture and component producers in Estonia, who has signed a license agreement with Välinge Innovation for the use of Threespine® click furniture technology.

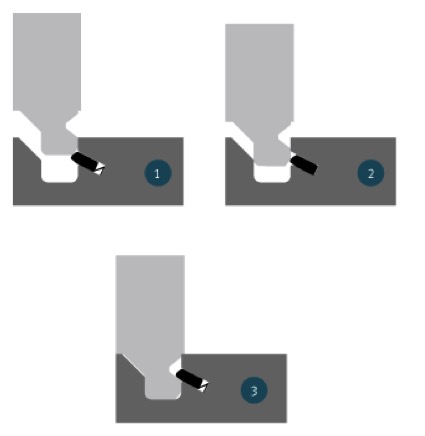

Threespine click furniture technology by Välinge enables furniture assembly in seconds without using any tools, screws, fasteners or other loose parts. Furniture just clicks together for perfect, stable results every time.

TNC-Components provides quality components and ready products from MFC, MDF, HDF and veneer to furniture sellers, DIY stores and building companies. The company is specialized in high-volume manufacturing and is today one of the leading regional suppliers to the furniture industry. Apart from its standard product line of kitchen cabinets, bathroom cabinets, wardrobes and door fronts, TNC-Components also manufactures specific customer products.

“Easy assembly, non-destructive disassembly and improved stability are advantages that will attract new customers. By implementing Threespine, we will thereby be able to offer our clients products with added value while our company simultaneously will save time and money. In addition, the technology will significantly impact the production and packing processes as there is no need for extra tools and assembly fittings”, says TNC-Components Plant Manager Marko Melter.

As a part of TNC-Component’s implementation of Threespine, the company has invested in a new profiling line from Homag. The new production set-up will, according to Marko Melter, open up new business opportunities for the company.

“We plan to start with the implementation of Threespine in kitchen furniture and wardrobes. Next step will be to expand to all other products lines but we are also open to develop new products with this technology, both for existing and new customers”.

The target is to launch the new production line during the summer of 2019 and to release the first products later in the same period.

0 Comments