SOUTH AMERICA – A consensus is clearly forming in the global furniture industry regarding the quality differentiation benefits of glue less “zero joint” edgebanding when compared to traditional edge hotmelt processing.

And as processing technology for “zero joint” evolves, new and more accessible technology solutions are making this high end finish available to mid and small manufacturers, as manifested by various South American furniture manufacturers.

The first technology developed for “zero joint” was laser technology. Albeit being the one that requires more investment, it is still considered by major manufactures as the preferred option. Such is the case of Germany’s main Kitchen and Office Furniture manufacturers that target the high end market. Here, most leading brands opted for laser technology as the “zero joint” solution for end customers.

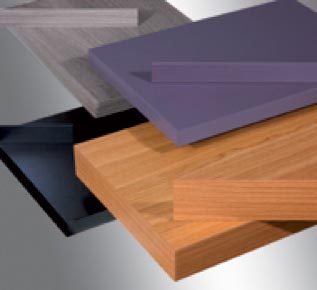

As edgebanding processing technology evolved, Hot Air technologywas introduced becoming a viable option for mid and small manufacturers, as it requires less of an investment effort. As with laser technology, Hot Air technology processes special plastic co-extruded edge that is manufactured in Europe, mainly in Germany by Doellken and Rehau.

Furniture manufacturers in South America are aware of the advantages associated with a better edge finish and are evaluating their options for “zero joint” processing technology. The main obstacles that are perceived are investment costs and future local availability and distribution of the special coextruded plastic edges.

In this scenario some manufacturers in the region are considering a PUR adhesive alternative with traditional hot melt edge processing. PUR adhesives have no fillers, allowing the use of traditional PVC edge that is locally available to achieve a “zero joint” finish. The downside of the PUR alternative is the difficulties and complexity related with the proper handling of this adhesive. Time will tell what technology the regional market adopts for a “zero joint” finish, but as Notifix was able to confirm, “zero joint” will be a reality sooner than later in South America.

0 Comments