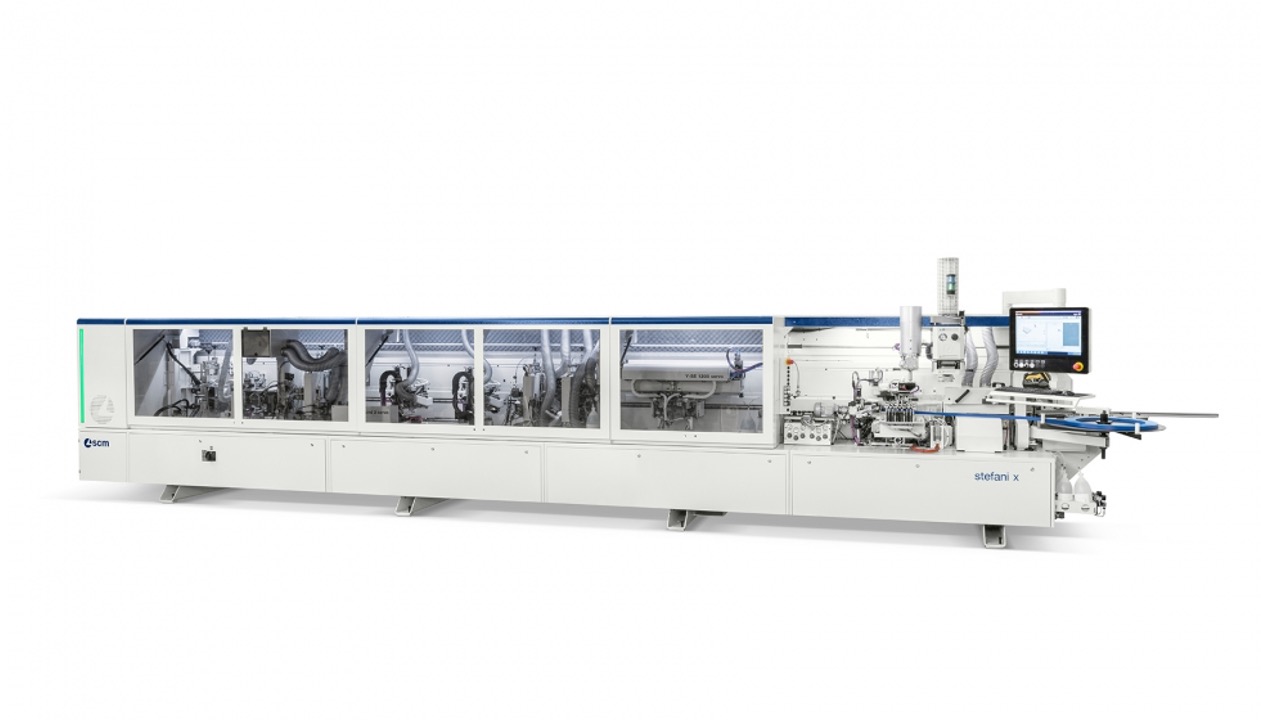

ITALY – SCM Group´s new industrial edgebanding machine has been designed to offer top quality machining on any kind of panel and material, to fully meet the needs of a connected and integrated digital factory.

The result is a highly configurable, customised edgebanding machine, designed to reliably work several shifts and capable of providing top-quality machining, both in the stand-alone version and in integrated cells or lines.

One other important advantage is its ability to achieve maximum quality standards easily and without interruption, even on the most delicate, state-of-the-art materials, thanks to SCM’s new electronic touch systems.

“This new edgebanding machine is a further advancement to accompany and support designer furniture businesses in optimising their production processes together with the technological innovation and know-how acquired by SCM in the edgebanding sector over a period of seventy years – highlights SCM’s Edgebanding Business Manager, Fabio Cernoia -.The new “stefani x” is proof that an edgebanding machine needs to be much more than a machine. In fact, it needs to be an all-round technological project that is highly configurable and versatile, where it is the quantitative and qualitative composition of the units that make a difference to the panel machining process”.

0 Comments